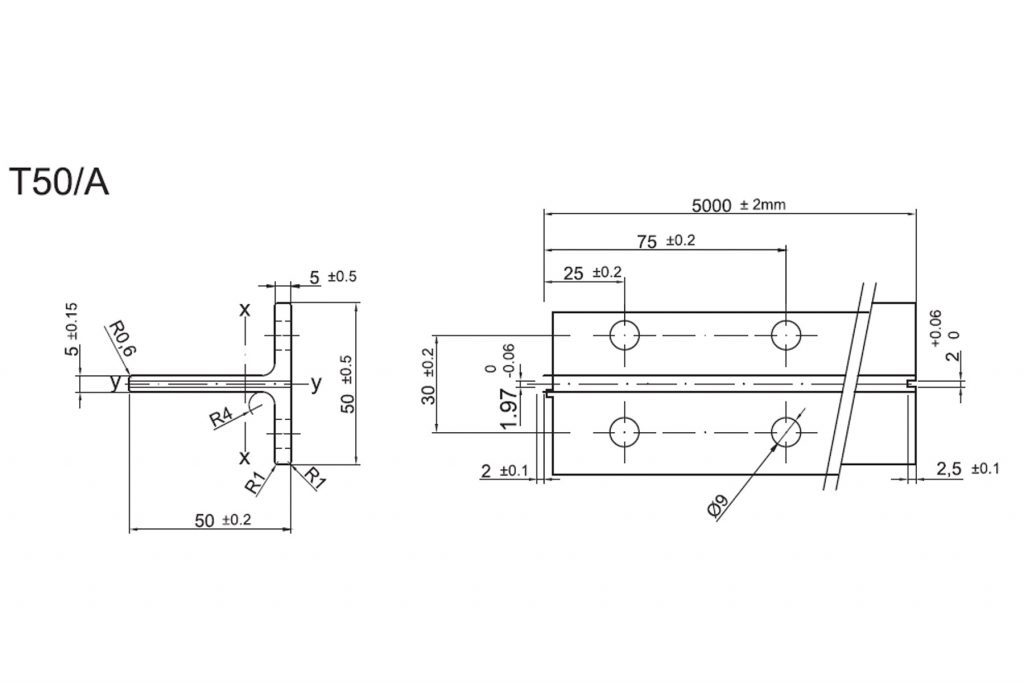

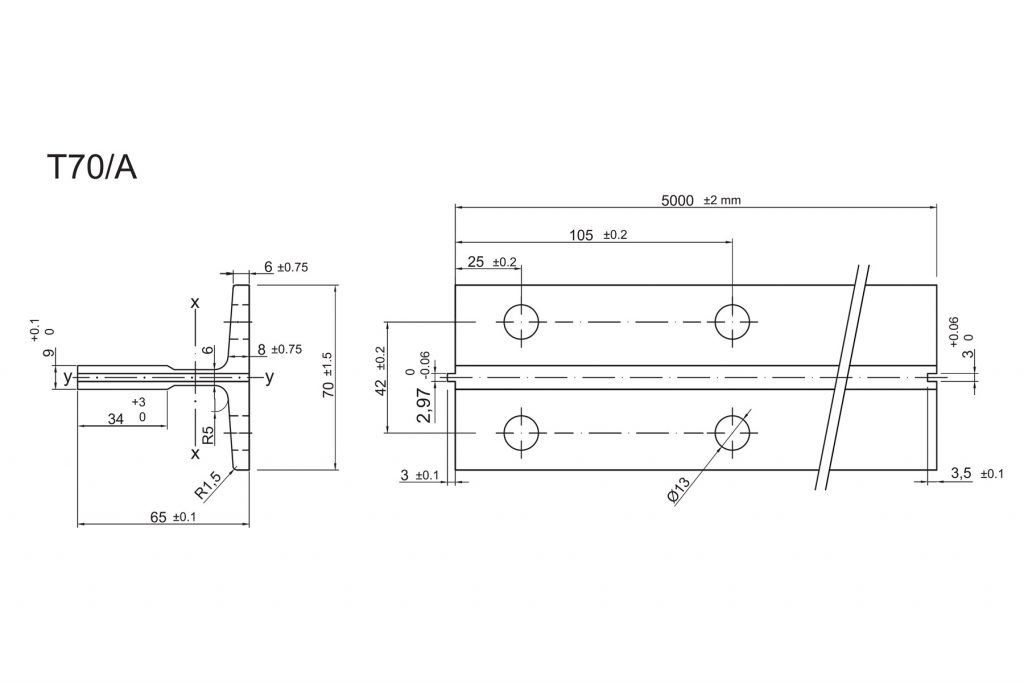

At present, this factory produces two types of the most widely used elevator guide rails in the country, namely T50 / A and T70 / A rails in the factory production line for consumers.

The elevator guide rail is responsible for guiding the elevator cabin in the direction of vertical movement of the cabin so that if an unbalanced load is applied to the cabin floor, it will not cause the car to be unbalanced. Another function of the elevator guide rails is emergency braking when parachuting due to the unusual speed of the cabin.

Excessive surface stiffness or softness outside the standard elevator guide rail will prevent the cabin from stopping in time or the rail from bending during emergency braking.

Elevator guide rails are produced in two groups: Cold drawn and in class A / and machined in class B / and BE /.

The elevator guide rails produced by the world’s reputable factories for different speeds and in different classes are given in the table opposite

Cold tension elevator guide rail wings are produced in two groups of parallel wings and sloping wings.

Today, due to the existence of skyscrapers, elevator guide rails are also made stronger and more accurate so that they can withstand high speeds and forces applied to the rails. All elevator guide rails made for high speeds are cracked by the ultrasonic device in the quality control process.

The cold traction rails of this factory, like the rails of the largest production factory in Italy, are suitable for cabin speeds of less than 2 meters per second and are used for buildings up to 10 floors.

To inquire about the price, you can call +98 (21) 5680 7200-3 or contact our Sales experts in the sales department by the form below.